Product use:RIP condenser transformer/reactor bushings are mainly used in power transformers/reactors, working as the current carrying conductors for pulling in or drawing high, medium and low voltage side current of transformers/reactors, and playing a role of insulation for oil tank shell of transformers/reactors.

Service conditions:

· Altitude: 1000m (products can be designed according to altitude correction coefficient if altitude is higher than 1000m)

· Ambient air temperature: -45℃- +60℃

· Installation angle: arbitrarily

Product structure: it is mainly composed of conducting pole, RIP capacitor core, high temperature liquid silicone rubber composite external insulation, equalizing ball, test tap, fittings, etc.

Advantages of bushings:

Ø Unique resin system and special buffer strips

Ø The most advanced production equipment of the world guarantee the better electrical properties, heat-resistance and mechanical properties of RIP bushings series.

Ø The lower weight and smaller volume make it easy for transportation, erection and maintenance.

Ø Oil-free and gas-free design is more environmentally friendly, no risk of explosion;

Ø Excellent performance ensures long-term stable online operation.

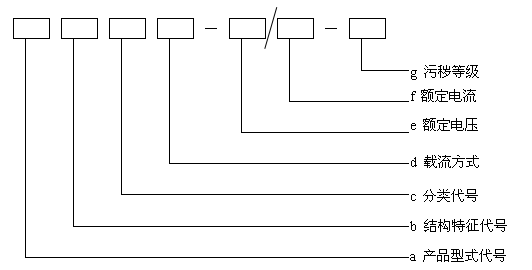

Description of product type

a Product type code

· BRFG Composite insulated RIP condenser transformer bushing

·BRCG Porcelain insulated RIP condenser transformer bushing

·BRQG Oil- SF6 RIP condenser transformer bushing

·BROG Oil- oil RIP condenser transformer bushing

· CRFG Composite insulated RIP condenser wall bushing

·CRCG Porcelain insulated RIP condenser wall bushing

· DRFG Composite insulated RIP condenser generator bushing

·GRFG Composite insulated RIP condenser GIS outlet line bushing

b Structural features code

L means it can be equipped with current transformers; no L means it can not be equipped with current transformers.

c Classification code

DC bushings are indicated with the letter Z; AC bushings are not expressed.

d Way of current carrying

1-Direct type;2-Cable through type

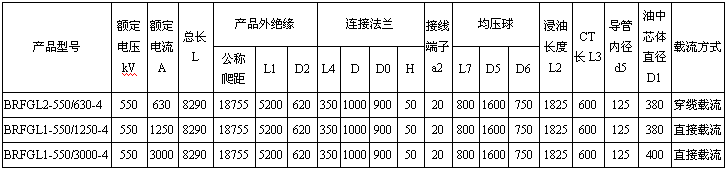

TableⅠ Electrical performance table of oil - air dry-type condenser transformer/reactor bushings

|

Systemic nominal voltage Un kV

|

35

|

66

|

110

|

132

|

150

|

220

|

330

|

420

|

500

|

|

Rated voltage Ur kV

|

40.5

|

72.5

|

126

|

145

|

170

|

252

|

363

|

420

|

550

|

|

Maximum working phase voltage for equipment Ur/ kV kV

|

23.5

|

42

|

73

|

84

|

98.5

|

146

|

210

|

242

|

317

|

|

60s Power frequency withstand voltage

|

Dry kV (r.m.s)

|

95

|

155

|

255

|

305

|

355

|

505

|

625

|

695

|

870

|

|

Wet kV(r.m.s)

|

80

|

140

|

230

|

275

|

325

|

460

|

535

|

680

|

790

|

|

Lightning impulse withstand voltage

|

Full wave kV (peak)

|

200

|

325

|

550

|

650

|

750

|

1050

|

1175

|

1425

|

1800

|

|

Chopped wave kV (peak)

|

-

|

-

|

635

|

750

|

865

|

1210

|

1495

|

1639

|

2070

|

|

Switching impulse withstand voltage (dry or wet) kV (peak)

|

-

|

-

|

-

|

-

|

-

|

850

|

950

|

1050

|

1300

|

|

Dielectric loss %

|

Added value (not more than)

|

1.05Ur/ - Ur: 0.1 - Ur: 0.1

|

|

Maximum value

|

40.5kV - 363kV

|

0.6, measured at the voltage of 1.05Ur/

|

|

420kV - 550kV

|

0.5, measured at the voltage of 1.05Ur/

|

|

Partial discharge at the voltage of Ur (not more than) pC

|

10

|

Schematic diagram of 72.5kV and 126kV dry-type condenser transformer bushing

Main dimensions of 72.5kV and 126kV dry-type condenser transformer bushings

Unit:mm

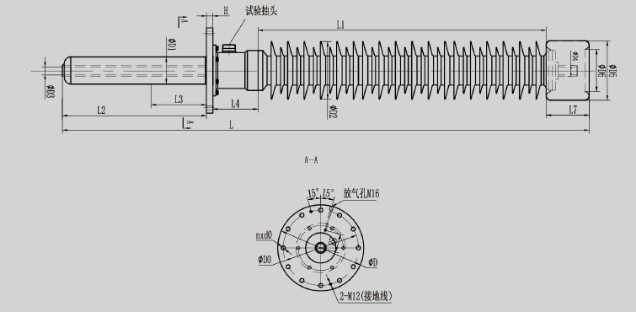

Schematic diagram of 145kV and 170kV dry-type condenser transformer bushing

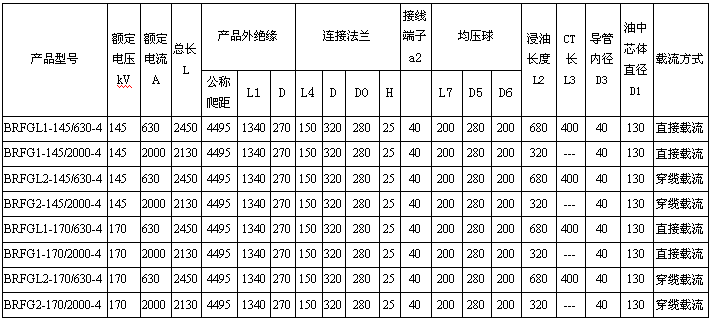

Main dimensions of 145kV and 170kV dry-type condenser transformer bushings

Unit:mm

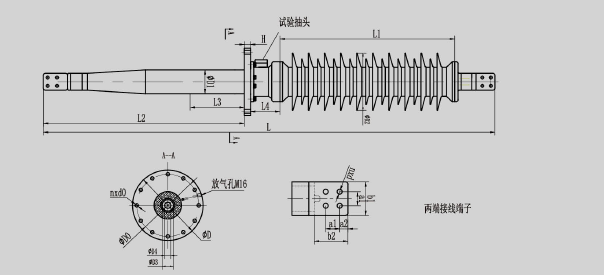

Schematic diagram of 252kV and 550kV dry-type condenser transformer bushing

Main dimensions of 252kV dry-type condenser transformer bushings

Unit:mm

Main dimensions of 550kV dry-type condenser transformer bushings

Unit:mm